CAD Design Solution -

Aimed at enhancing the efficiency and accuracy of the mold design process, NW provides the complete solution for the entire mould development cycle. Specially baked tools on the mould cavity, copper electrodes, standard mould-base design makes the entire mould design process easier than ever before. To provide seamless integration with your existing working environment, NW develops the solution on the commonly adopted Solidworks platform.

Not satisfied with tradition CAD solutions, NW also provides customization on the mould design to minimize the design inconsistence while squeezing the design time. The customized CAD modules consist of:

|

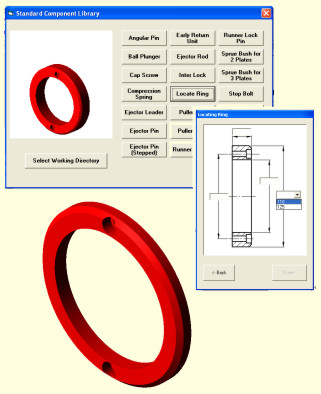

Component Standardization ¡V Standardize the component library for your mold design to ensure the design consistency and achieve a shorter design cycle by creating the component in Solidworks with a few click. |

|

Mould Base Standardization - Similarly, the mould base standardization provides the immediate solution for mould-base design. Besides the commonly used mould base such as Futaba, we cover, also, the Lung Kee and Ming Lee mould base specially crafted for East-Asia market.

|

|

CAM Customization -

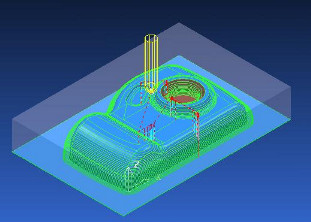

In a mold making cycle, machining (drilling, boring, milling, turning etc.) is a key process and larger number of components such as copper electrodes, mold cores, mold cavities, mold components and mold plates are manufactured or machined in this procedure. There are different CAM platforms available in the markets for generating the NC tool paths and in general.

|

Different machining strategies are provided in the platforms. |

|

Machining parameters are set according to the machining conditions (tools, materials, machining centres and parts' geometries). |

|

Usually machining strategies and parameters are determined by NC programmers' experiences. |

|

Inconsistent machining parameters and strategies for different NC programmers. |

CAM customization services are provided in order to minimize the problems of inconsistent tool path generation in general CAM platforms. A customized CAM module consists of:

|

|

Develop knowledge-based machining libraries which contain the information of the machining centers and cutting tools used by the customers. |

|

Use the libraries to assist NC programmers to determine optimal machining parameters . |

|

Integrate customers' machining strategies into the customized CAM module |

|

|