Our CAPP consultancy is dedicated on helping manufacturer

to develop workshop information system in order to bridge the

information gap existed in the distributive located manufacturer.

We help customer to tailor-make their own MRP

system based on their workshop culture. The customization services

include developing system to capture the information of various

manufacturing resources.

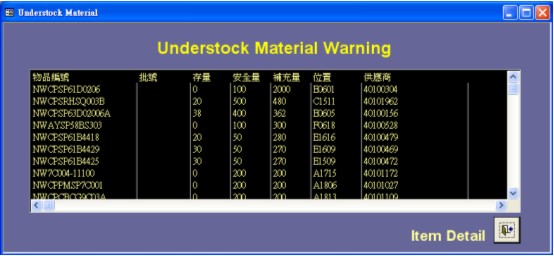

For managing a components warehouse, inventory control is developed

to maintain the inventory policy. Information such as components/products

stock level, safety level and order level, are kept in the system.

Daily components In-Out activities can be controlled through

the system. To implement a corresponding inventory control policy

in a workshop, consulting services will be provided together

with the system.

For tracing the status of job, monitoring system

is developed to update the status of job. These information

included status of components from external vendors, status

of parts to be made, schedules, status and utilization of the

machines. Similarly, corresponding process control policy can

be established via our consulting services.

The above mentioned information can be easily

inquired via internet interface. Customer can thus be benefited

from the flexibility of working hour, independent of working

location and enjoy the mobile management. With the tight linking

of our CAD/CAM customization service, the resources planning

can be earlier realized at design period and the production

planning can be carried out smoothly.